Introduction: The Bright Side of India’s Packaging Revolution

India’s packaging industry is experiencing a historic transformation. With rapid urbanization, booming e-commerce, and increasing consumer awareness, the sector is projected to cross USD 200 billion by 2025. From food containers to industrial films, packaging is no longer just about protection — it’s about presentation, performance, and sustainability.

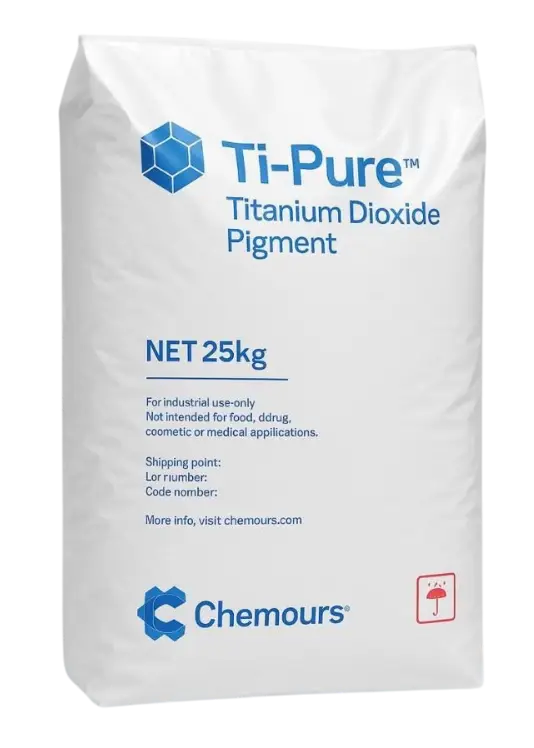

At the core of this evolution lies a critical ingredient: Titanium Dioxide (TiO₂). Known for its exceptional whiteness, opacity, and UV resistance, Titanium Dioxide enhances the appearance and durability of packaging materials.

As one of the most reliable Titanium Dioxide Distributors in India, Aanya Enterprise delivers tailored pigment solutions that support the packaging sector’s growth — ensuring brilliance, cost efficiency, and long-term performance.

Why Titanium Dioxide Matters in Packaging

Titanium Dioxide plays an essential role in the visual and functional performance of packaging materials. Its high refractive index allows it to scatter light effectively, producing intense whiteness and opacity even at low concentrations.

In packaging, TiO₂ is used to:

- Provide bright, clean appearance to films and containers.

- Enhance opacity, ensuring the contents are shielded from UV light.

- Improve printability for labels and graphics.

- Increase mechanical strength by improving polymer crystallinity.

- Offer UV protection to preserve packaged goods and prevent discoloration.

For industries like food, cosmetics, pharmaceuticals, and FMCG, Titanium Dioxide ensures that packaging looks appealing, remains stable, and maintains product integrity throughout its lifecycle.

Applications of Titanium Dioxide in the Packaging Sector

Titanium Dioxide finds application across multiple packaging formats:

a. Flexible Films

Used in BOPP, PET, and PVC films, TiO₂ provides opacity, gloss, and barrier protection against UV and moisture. It enhances the overall aesthetic and extends the shelf life of light-sensitive products.

b. Rigid Containers and Bottles

In injection-molded and blow-molded packaging, Rutile-grade TiO₂ improves whiteness and durability while protecting against UV degradation.

c. Laminated Packaging

For multilayer packaging materials, TiO₂ ensures uniform color and superior print quality, enabling premium branding and product presentation.

d. Label and Graphic Films

TiO₂ enhances brightness and print contrast, essential for brand labeling and barcode clarity.

e. Food and Pharmaceutical Packaging

Anatase-grade TiO₂, being chemically inert and food-safe, is preferred for applications where contact safety and purity are critical.

Rutile vs. Anatase Titanium Dioxide for Packaging

Understanding the difference between Rutile and Anatase grades helps packaging manufacturers choose the most efficient option:

- Rutile Grade: Offers better opacity, UV protection, and heat stability. Ideal for outdoor-exposed packaging like industrial drums or reusable containers.

- Anatase Grade: Provides a bluish-white tone and excellent dispersion. Ideal for indoor, food-grade, or aesthetic packaging applications.

Aanya Enterprise supplies both grades, enabling clients to choose based on their performance and cost requirements.

Packaging Industry Growth in India: A Snapshot

The Indian packaging market is one of the fastest-growing globally, fueled by:

- E-commerce expansion and logistics optimization.

- Sustainability demand, driving lightweight, recyclable materials.

- Urban consumer growth, increasing demand for packaged goods.

- Technological advances, including digital printing and smart packaging.

As the sector grows, manufacturers are increasingly focusing on appearance, barrier properties, and sustainability—all of which are directly influenced by Titanium Dioxide pigments.

Key Benefits of Titanium Dioxide in Packaging Materials

1. Enhanced Opacity and Whiteness

Even at low pigment loadings, TiO₂ ensures high hiding power, enabling manufacturers to achieve bright and consistent color across batches.

2. UV and Heat Protection

Rutile TiO₂ acts as a shield against UV degradation, preventing polymer yellowing and maintaining product quality under sunlight exposure.

3. Cost Optimization

High tinting strength allows for reduced pigment usage without compromising brightness, lowering overall material costs.

4. Print Clarity and Surface Smoothness

Titanium Dioxide improves surface smoothness, ensuring sharp print resolution — vital for premium packaging designs.

5. Sustainability and Recyclability

Modern TiO₂ grades are eco-friendly and compatible with recyclable polymer systems, supporting India’s green packaging goals.

How Aanya Enterprise Supports the Packaging Industry

As a leading Titanium Dioxide Distributor in India, Aanya Enterprise provides customized pigment solutions for packaging manufacturers, ensuring performance and consistency.

Our Capabilities Include:

- Multiple Grade Options: Both Rutile and Anatase grades tailored for film extrusion, molding, and coating applications.

- Technical Support: Guidance on pigment dispersion, loading ratios, and optical optimization.

- Supply Reliability: Nationwide distribution ensuring on-time delivery and batch consistency.

- Cost-Effective Solutions: Flexible sourcing from domestic and global TiO₂ manufacturers to balance performance and price.

- Sustainability Focus: Environment-friendly grades supporting low-VOC, food-safe, and recyclable packaging materials.

Common Challenges in TiO₂ Use — and How Distributors Solve Them

Challenge 1: Dispersion Difficulties in Polymer Systems

Improper dispersion leads to agglomeration, reducing opacity and gloss.

Solution: Aanya Enterprise recommends surface-treated grades with silica or alumina coatings for smoother blending and higher dispersion.

Challenge 2: Yellowing During Processing

High-temperature processing can cause polymer yellowing.

Solution: Rutile TiO₂ grades with excellent thermal stability and low reactivity reduce discoloration.

Challenge 3: Cost Pressures

Price fluctuations in global TiO₂ supply can strain manufacturers.

Solution: Long-term supply contracts and blended grade strategies offered by Aanya Enterprise stabilize pricing and maintain quality.

Challenge 4: Sustainability Compliance

Regulations demand eco-friendly, recyclable pigments.

Solution: Aanya Enterprise provides low-VOC, non-toxic TiO₂ grades approved for food contact and sustainable manufacturing.

Case Studies: TiO₂ Success in Indian Packaging

Case Study 1 – Flexible Film Manufacturer (Gujarat)

A packaging company needed consistent whiteness across multilayer BOPP films. Aanya Enterprise provided a Rutile TiO₂ grade with superior dispersion, reducing pigment consumption by 12% and achieving higher brightness.

Case Study 2 – Food Packaging Supplier (Maharashtra)

To meet food safety standards, the client adopted Anatase TiO₂ recommended by Aanya Enterprise, achieving FDA-compliant packaging with improved gloss and opacity.

Case Study 3 – Industrial Packaging Producer (Tamil Nadu)

Facing UV degradation issues in outdoor drums, the manufacturer switched to a weather-resistant Rutile grade, extending product life by 30%.

Titanium Dioxide and Sustainable Packaging

Sustainability is a defining trend in 2025. Brands are shifting towards eco-friendly, recyclable materials, and TiO₂ plays a vital role in enabling this shift.

- Recyclable Polymers: TiO₂ is compatible with recyclable PE, PP, and PET films.

- Low-VOC Production: Supports the move towards cleaner manufacturing.

- Photocatalytic Applications: Certain Anatase grades help in air-purifying packaging solutions.

Aanya Enterprise aligns with sustainability goals by supplying eco-compliant Titanium Dioxide grades that meet global environmental standards while maintaining high performance.

The Aanya Enterprise Advantage

Why Partner with Us:

- Trusted Titanium Dioxide Distributor in India with nationwide reach.

- Access to global brands such as Lomon Billions, Venator, and Tronox.

- Application-specific grades for films, coatings, and molded packaging.

- Technical expertise for formulation support and optical optimization.

- Consistent supply and transparent pricing to help clients plan ahead.

Aanya Enterprise acts not only as a supplier but as a strategic partner, helping packaging manufacturers balance performance, cost, and sustainability.

Market Outlook 2025: Packaging and Titanium Dioxide Demand

The Indian packaging industry’s growth trajectory ensures continuous demand for Titanium Dioxide:

- Flexible packaging to dominate due to e-commerce expansion.

- Food-grade TiO₂ to see higher consumption amid safety regulations.

- Eco-friendly coatings and films to drive innovation in pigment formulations.

- Stable price trends expected as domestic TiO₂ production increases.

For manufacturers, this means long-term opportunities — provided they partner with distributors who offer consistent quality and proactive market insights.

Conclusion: Empowering India’s Packaging Future

The packaging sector’s success depends on innovation, quality, and sustainability — and Titanium Dioxide plays a central role in achieving all three.

From achieving brilliant whiteness and superior printability to ensuring UV stability and eco-compliance, TiO₂ remains indispensable in modern packaging.

Aanya Enterprise, as a trusted Titanium Dioxide Distributor in India, continues to support packaging manufacturers with premium-grade pigments, expert advice, and stable supply chains — helping India’s packaging sector shine brighter, perform better, and move toward a sustainable future.